Metabolic Engineering of Yeast for Dicarboxylic Acid Production – an Important Intermediate in the ACTPAC Project

What is metabolic engineering?

The focus of metabolic engineering are biochemical pathways. Pathways describe a sequence of reactions within a cell to build up a product that is a (small) organic molecule. Each reaction in the pathway is usually catalyzed by a separate enzyme. With metabolic engineering, one can intentionally modify these pathways, generally with the aim to increase production of a wanted product that is part of a pathway [1,2]. This can be achieved rationally by different means, for example by (1) increasing the amount of the pathway enzymes in the cell (by adding enzyme gene copies or adapting the promoters), (2) deleting the genes for enzymes of pathways using up the wanted product or mutual resources, (3) introducing genes for enzymes from other organisms that catalyze a reaction of interest [1,2].

Why is metabolic engineering of yeast strains of interest for long-chain dicarboxylic acid production?

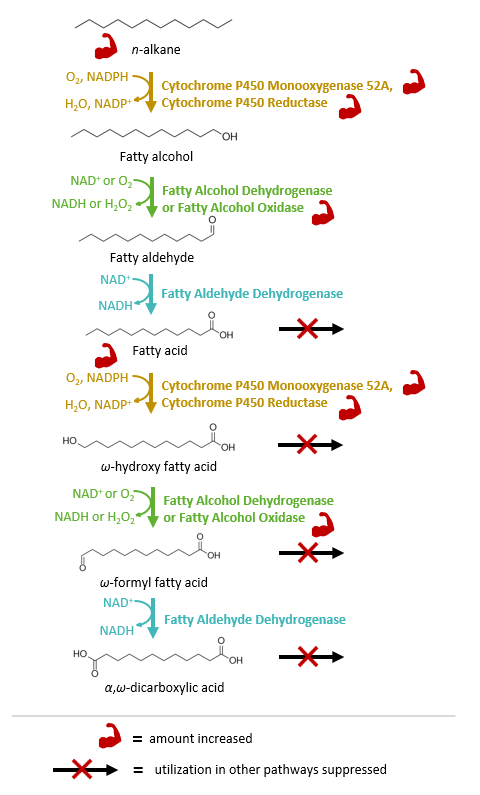

In the ACTPAC project we break up polyethylene (PE) into smaller molecules, alkanes, for PE recycling. For the further recycling steps, it is crucial to introduce functional groups only at both ends of the alkanes and not somewhere else in the middle. This is chemically challenging, but some yeast strains like Candida viswanathii developed a special pathway to process alkanes and use them for energy gain [3,4]. In this so-called α,ω-oxidation pathway, only the carbon atoms at the end of alkanes are oxidized, leading to our wanted product, the dicarboxylic acids (Figure 1) [3,4]. This is very advantageous for the ACTPAC project’s goal and can be subject to metabolic engineering to enhance dicarboxylic acid production.

How is metabolic engineering of Candida viswanathii employed to enhance dicarboxylic acid production?

Two of the three main principles of rational metabolic engineering have already been applied to reach higher dicarboxylic acid productions in Candida viswanathii. The first step was to prevent products of the α,ω-oxidation pathway to be subjected to other pathways. Naturally, the yeast would do so in order to gain energy, but Picataggio et al. (1992) impeded this process by deleting genes for enzymes of other pathways in the yeast’s genome, reaching a first milestone in biological dicarboxylic acid production [3].

Pham et al. (2023) made use of another big principle in rational metabolic engineering and looked into the α,ω-oxidation pathway itself. They identified two of the three enzymes of the pathway (cytochrome P450 monooxygenase 52A, fatty alcohol oxidase) as bottlenecks [4]. They also found two crucial enzymes that assist the pathway by either directly supporting an enzyme of the pathway (cytochrome P450 reductase) or ensuring the availability of the needed reaction partner NADPH (NADH kinase) [4]. They added copies of all these five enzyme genes to the yeast’s genome and achieved another milestone by producing more than 200 g/L of dicarboxylic acids [4]. With these two milestones, the groundwork for further optimization and specialization in dicarboxylic acid production was laid out with more interesting research to come.

Author: Sina Becker

Links

[1] Woolston, B. M., Edgar, S., & Stephanopoulos, G. Metabolic engineering: past and future. Annual review of chemical and biomolecular engineering, 4(1), 259-288 (2013), https://doi.org/10.1146/annurev-chembioeng-061312-103312.

[2] Volk, M. J., Tran, V. G., Tan, S. I., Mishra, S. et al. Metabolic engineering: methodologies and applications. Chemical reviews, 123(9), 5521-5570 (2022), https://doi.org/10.1021/acs.chemrev.2c00403.

[3] Picataggio, S., Rohrer, T., Deanda, K. et al. Metabolic Engineering of Candida Tropicalis for the Production of Long–Chain Dicarboxylic Acids. Nature Biotechnology 10, 894–898 (1992), https://doi.org/10.1038/nbt0892-894.

[4] Pham, N. N., Chang, C. W., Chang, Y. H. et al. Rational genome and metabolic engineering of Candida viswanathii by split CRISPR to produce hundred grams of dodecanedioic acid. Metabolic Engineering, 77, 76-88 (2023), https://doi.org/10.1016/j.ymben.2023.03.007.

Keywords

Alkane to dicarboxylic acid conversion, biotransformation, metabolic engineering, α,ω-oxidation pathway, Candida viswanathii, yeast, plastic recycling